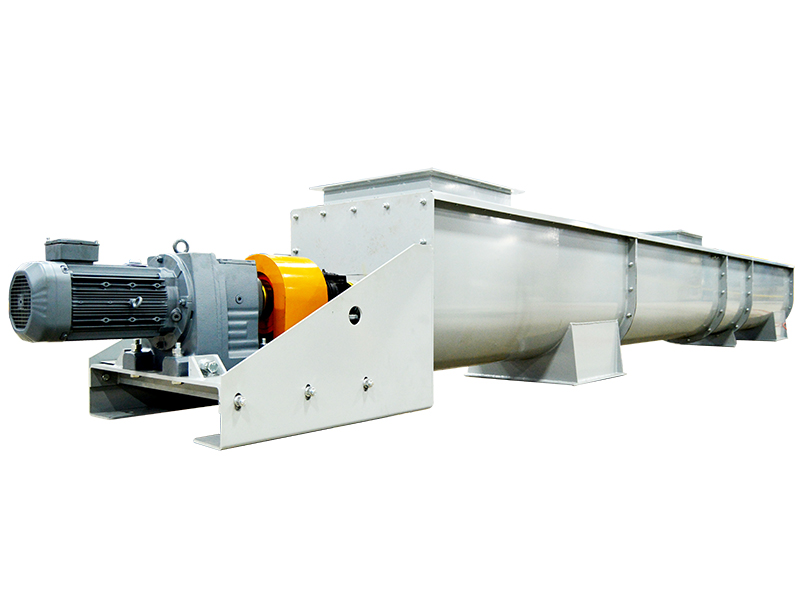

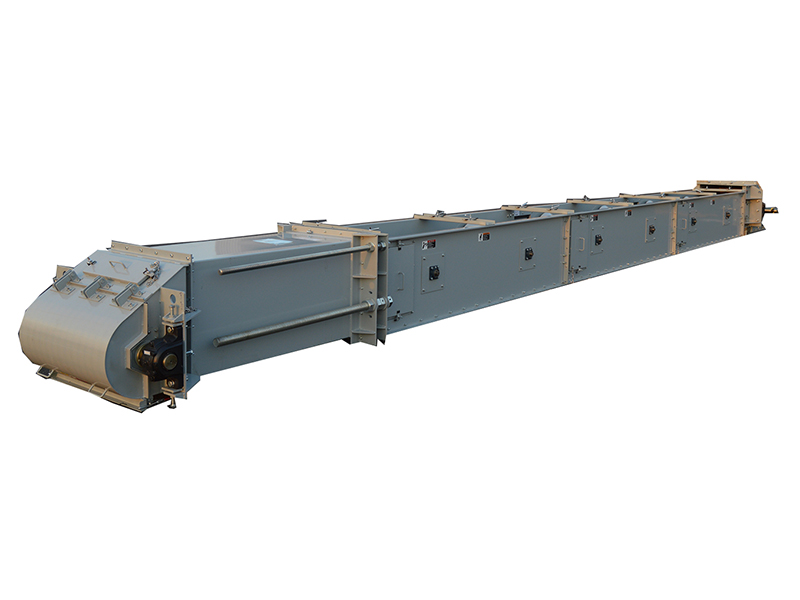

Enclosed Belt Conveyors

+Low Energy Consumption

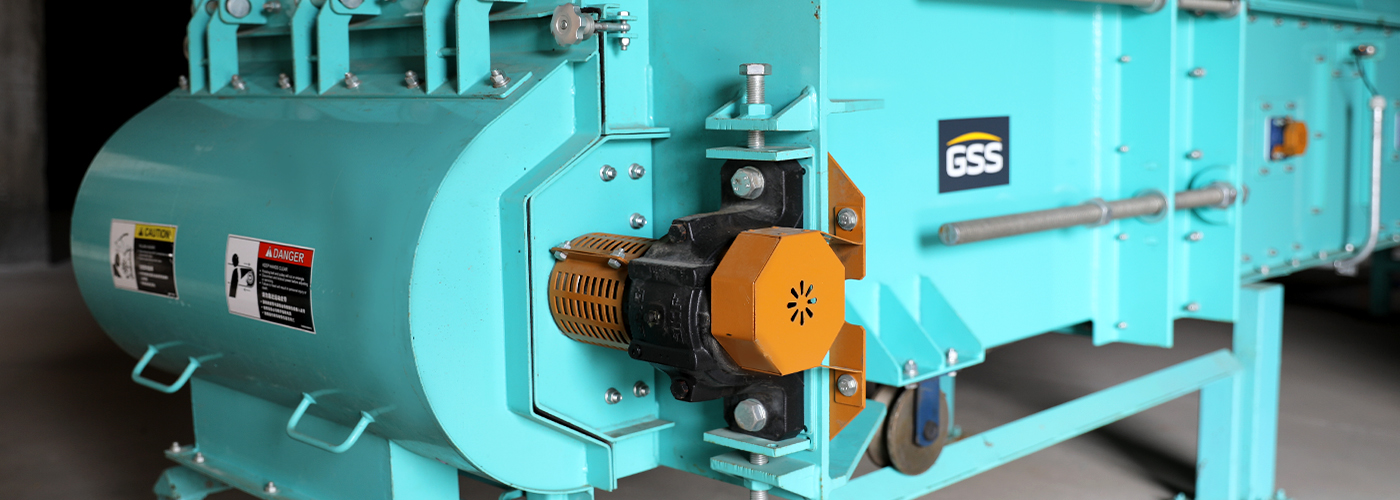

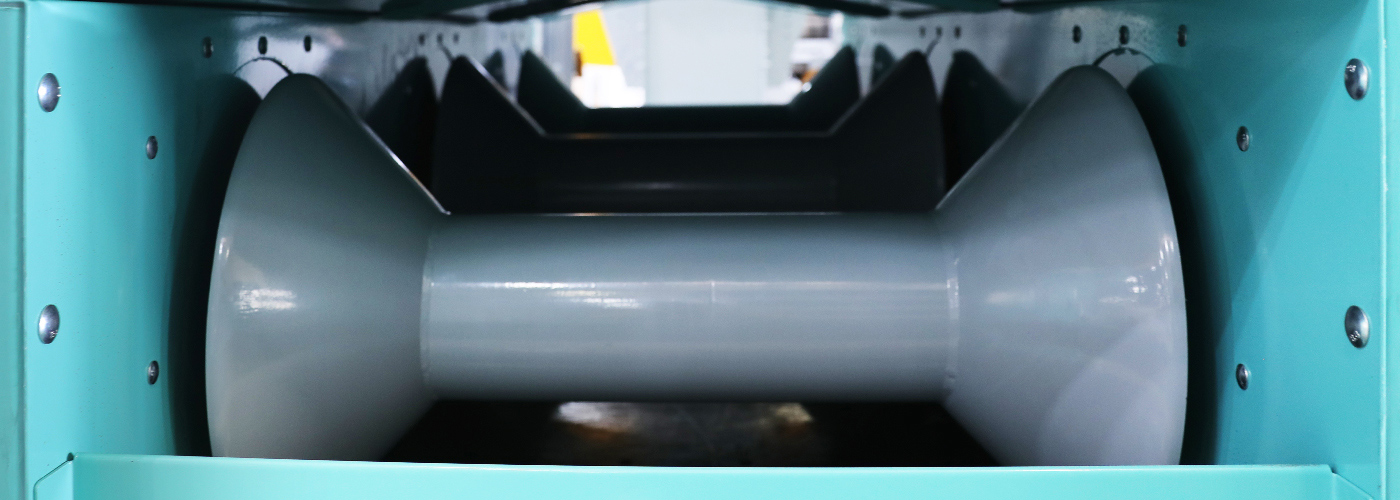

Single roller & trouble-free design

Self-clean

Dust accumulation & clogging free

Fully Enclosed

Environmentally friendly & no dust escape

Features

Optional Accessories

Fiber optic tempering system

If you need technical support, please fill in the blanket below and submit it, we will do our best to help you.

Please leave your message below:

把您的留言写在这里,然后提交给我们