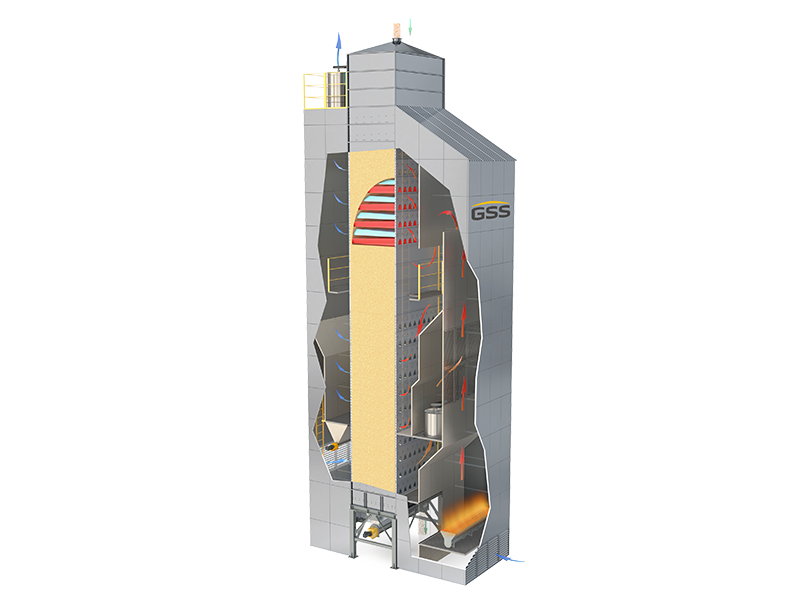

Mix-flow Process Dryers

+Low Temperature

Low temperature technology effective protection for grain quality and reduced stress of the grain. The operator can adjust the temperature of the dryer according to the different requirements of the grain being dried.

Automation & Intelligence Processing

PLC control system allows for flexible control of dryer operation with parameters fully displayed on HMI touchscreen. Step-less discharge speed adjustment.

Low Drying Cost

The GSS Dryer is designed with multi-fuel availablity, such as steam, natural gas, oil, and biomass. Up to 90% of the hot air generated can be recirculated for grain drying, resulting in reduced drying costs.

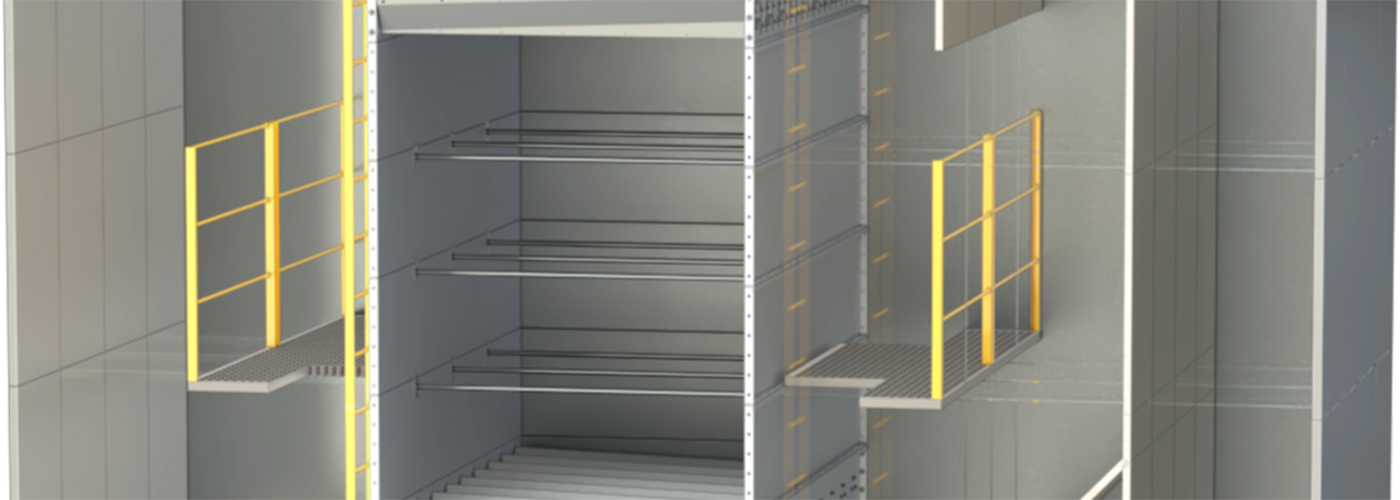

Features

If you need technical support, please fill in the blanket below and submit it, we will do our best to help you.

Please leave your message below:

把您的留言写在这里,然后提交给我们