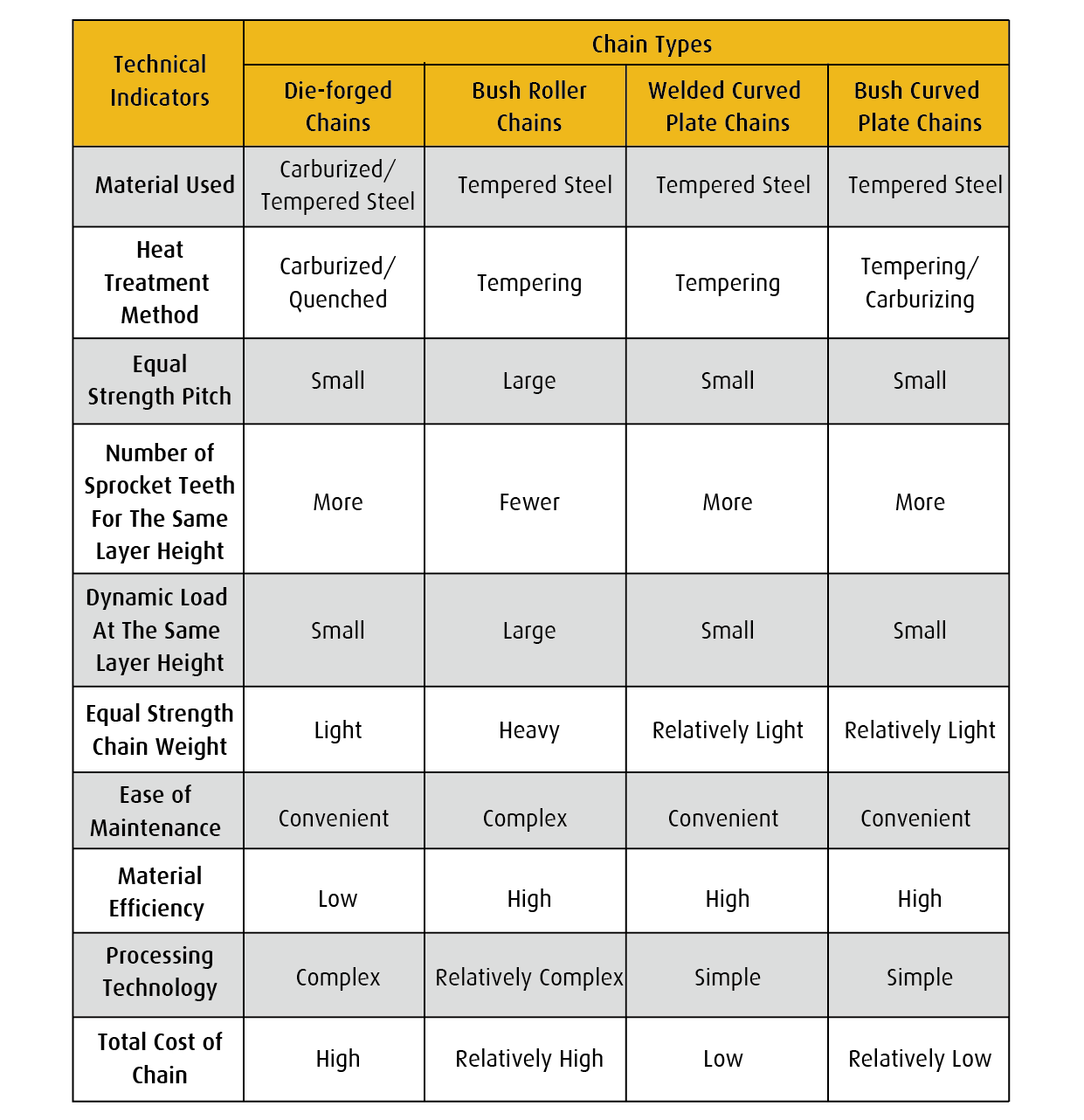

Based on the previous discussion regarding the manufacturing, materials, heat treatment, and practical testing of various commonly used chains, the comprehensive comparison information is presented in Table below:

Choosing the appropriate chain based on different materials and the operating environment of the chain is a key measure to extend the chain’s lifespan and reduce maintenance and repair costs. The applicable environments for commonly used chains are as follows:

1. Die-forged chains are mostly suitable for lightweight or high wear-resistance scraper conveyors and are also applicable to conveying conditions with minimal residual materials on the chain.

2. For relatively clean conveying environments, where adhesion is poor and the materials are large in volume but lightweight, bush roller chain can be used.

3. Welded curved plate chain are known for their strong overall performance, high strength, wear resistance, and excellent ability to withstand harsh conveying environments. They are suitable for high-capacity, all-weather conveying of various materials and for conveying materials with a certain level of adhesiveness, such as dust and soybean meal.

4. For working conditions requiring higher wear resistance for the bush, bush curved plate chain can be selected. However, due to their higher cost compared to welded curved plate chain and the limited availability of models, their actual demand in practical applications is relatively low.

Currently, welded curved plate chain have become the primary choice in the grain and oil conveying sector due to their relative advantages in fatigue resistance, strength, lifespan, and cost.

Post Time: 2025-03-31