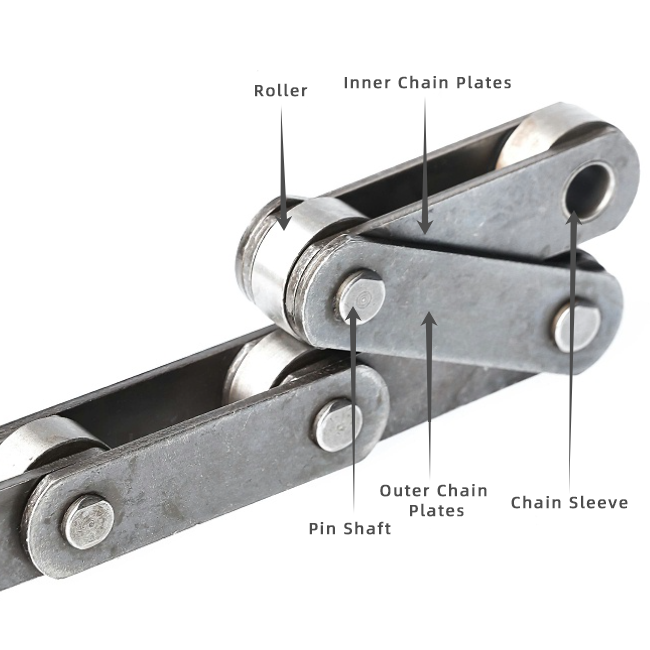

The bush roller chain consists of inner chain plates, outer chain plates, bushes, pin shafts, rollers, and chain accessories (as shown in Figure).

The chain plate is formed by the cutting process, and after precise machining, the roller is placed on the bush, which is then formed by interference pressing with the inner chain plates. The outer chain plate is connected to the inner chain plate using the pin shaft. The chain accessories can be installed either through welding or by assembly, depending on the requirements.

Figure: Bush roller chain (without chain accessories)

The materials for the chain plates, roller, and pin shaft are often made of 40Cr, quenched, and tempered, featuring high standardization, simple processing, and low cost. Furthermore, the engagement of the chain with the sprocket primarily involves the rollers meshing with the sprocket, allowing for free rotation and low pressure at the hinge points. The relative friction between the chain and the guide rails is also rolling friction, resulting in minimal wear and a longer lifespan. The replaceable chain accessories can also be used for conveying of various materials.

The bush roller chain has a relatively low tensile strength due to its components being assembled, making it unsuitable for excessive conveying loads. Additionally, the requirement of replacing chains in pairs also results in high maintenance costs. Moreover, under the same strength requirements, it is significantly heavier than other types of chains, making it appear relatively cumbersome.

Based on the characteristics of the bush roller chain, it is suitable for clean environments and the handling of large volumes of lightweight materials in the grain and oil industry. However, it is not suitable for conditions with high levels of corrosion and dust contaminants.

Post Time: 2025-02-09