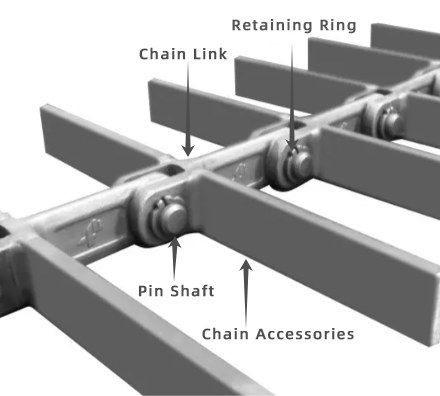

The die-forged chain, also known as the detachable chain, features a compact structure, lightweight design, and less material. It consists of chain links, pin shafts, retaining rings, and chain accessories (as shown in Figure). The chain links are made of alloy steel by die forging or roll forging. According to the structure, it is divided into three parts: large head, small head, and shaft.

According to the heat treatment process, it can be divided into two types: medium carbon steel die-forging chains and carburizing die-forging chains. The strengthening effect on the material’s fiber structure during the forging process, and the surface being treated through quenching or carburizing, exhibits high surface wear resistance and comprehensive mechanical properties. The chain accessories are connected to the chain links by welding.

The materials for links of the die-forged chain primarily include 40Cr and 20CrMnTi, which can be subjected to quenching and carburizing treatments respectively. The material for the pin shaft is mainly 40Cr, also treated through quenching. During the meshing process of the chain and sprocket, the meshing of the chain links, sprocket, and the rotation of the pin shaft with the chain links exhibit excellent wear resistance performance. The chain links are also manufactured through forging, which provides higher strength under the same specifications, allowing them to bear greater loads.

The material cost of a die-forged chain is relatively high, and the production process is complex, which results in a higher overall cost and longer production cycle. Additionally, when the production process is immature, there is a higher risk of quality defects and substandard performance are prone to occur. In applications, die-forging chains need to use wear-resistant materials due to the sliding friction with sprockets and guide rails, resulting in relatively high overall accessory costs.

According to the characteristics of die-forged chains, they have significant advantages in applications with high wear resistance and high strength requirement.

Post Time: 2024-12-22