The welded curved plate chain is commonly and widely used in the grain and oil industry due to its simple structure and good overall performance. It consists of chain links, pin shafts, pins, and chain accessories.

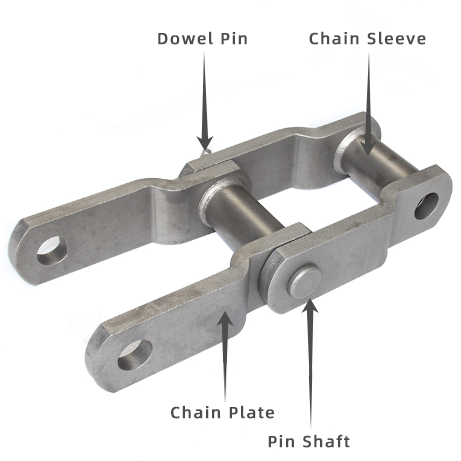

The chain links are formed by welding chain plates and bushes (see Figure). The materials for the chain plates and bushes are made of 40Cr, with the chain plates and pin shafts undergoing quenching treatment to enhance surface hardness and wear resistance. The bushes are hardened to surface high-frequency quenching to enhance wear resistance. (Some chains use localized high-frequency quenching on the chain plates to enhance the wear resistance of the friction surfaces.) The chain accessories are primarily connected to the chain links by welding.

The welded curved plate chain is manufactured entirely through welding, which provides good structural strength and allows it to withstand larger loads and impacts. Additionally, the wear resistance of the chain body is significantly enhanced after heat treatment, giving it high wear-resistant characteristics.

Due to the welding process for the welded curved plate chain, the bushes cannot undergo carburizing or high-frequency quenching heat treatment for the inner holes. Additionally, the chain accessories, which are also connected by welding, cannot be reinforced through treatment. As a result, issues such as bush wear and chain accessories breakage may occur.

The welded curved plate chain is widely used in the grain and oil industry, primarily suited for conditions that involve strong impacts, high loads, and a need for wear resistance.

Figure: Welded curved plate chain (without chain accessories)

Post Time: 2025-02-28