Primary causes of engineering chain runout

The runout of engineering chain refers to the phenomenon that the chain fails to keep on the set path or ideal trajectory in the process of running (as shown in Figure 1), and the primary reasons for this phenomenon can be categorized into the following types of reasons:

Figure 2 Engineering chain runout

2.1 Problems of the chain itself and treatment

Engineering chains are mass-manufacturing components. When manufacturing tolerances are exceeded, an entire chain segment may exhibit uniform deviations, causing defects or cumulative errors biased toward one side. Furthermore, improper installation or operation beyond permissible tolerance ranges can compound these deviations, ultimately leading to runout. Such problems can be categorized into the following reasons:

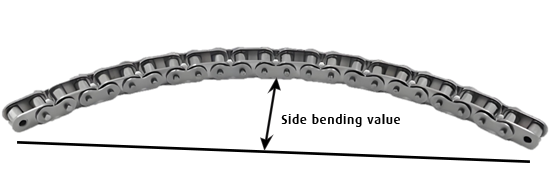

① Reasons due to engineering chain manufacturing: In the initial use process, there may be the case that the two sides of the engineering chain do not share the same amount of stretch, as shown in Fig. 3, the chain will be tested for side bending before leaving the factory, and the maximum distance between the inward and outward side bending and the horizontal line within a certain length of the chain is a1 and a2, and the difference between them is required to be in a certain range of values. As the permissible angle of side bending is set to a certain range, it may lead to the same direction of side bending in the same batch during the batch manufacturing, which leads to the phenomenon of unilateral runout during the initial use of the same batch of engineering chains. Secondly, if poor quality or poorly matched chain is used, the runout phenomenon will also occur during operation, and this kind of situation is less common.

Figure 3 Chain side bending test chart

② Reasons due to engineering chain installation: Since chains are driven by sprockets, failure to properly align and verify the sprockets before chain installation can easily lead to runout. Particularly when mispositioning occurs between the sprocket and chain, irregular tension distribution will develop in the chain, ultimately causing runout.

③ Reasons due to engineering chain wear: Prolonged operation leads to chain over-elongation, resulting in increased pin/bushing clearance and reduced tension. This causes chain oscillation or torsion during operation, ultimately inducing runout. Secondly, when new and old chains are mixed in the same equipment, this kind of situation is also more likely to happen.

2.2 Uneven load

During the operation of an en-masse conveyor, uneven material distribution during feeding – particularly when excessive material accumulates on one side – creates an imbalanced load on the chain. This forces the chain to shift toward the less-loaded side, resulting in runout.

2.3 Uneven rail or deformed intermediate section

Factors such as rail damage or unevenness on both sides, damage and deformation of the intermediate section also cause runout during operation of the engineering chain.

2.4 Material accumulation in intermediate section

Since there is a gap between the chain links of engineering chain and the rail or the base plate, viscous materials may accumulate. Due to chain movement, this accumulation becomes compacted and lifts the chain, causing floating chain and ultimately runout.

2.5 Insufficient maintenance or other reasons

Sprocket and chain wear during meshing may occur unevenly during prolonged operation. This can lead to unilateral sprocket wear or severe tooth tip wear. In such cases, even after chain replacement, the heavily worn sprocket will still cause poor meshing engagement with the new chain, ultimately resulting in runout.

Solutions

Proper chain operation depends on precise installation. When runout occurs, inspections should follow this priority order:

① The troubleshooting process should first verify whether conveyor housing deformation has occurred; if no deformation is present, the conveyor installation tolerances must then be inspected in accordance with applicable national standards, which stipulate that the symmetry deviation between the center planes of the head and tail sprockets relative to the theoretical center plane of the trough shall not exceed 2mm, while the complete En-Masse conveyor must simultaneously meet the following straightness requirements:

For equipment under 30m total length, straightness ≤5mm;

The straightness of the equipment with a total length more than 30m is ≤8mm;

The flatness of the base plate between two adjacent intermediate sections should also be ≤1mm.

② After ensuring the installation deviations are controlled within permissible tolerances, verify the internal guide rail coplanarity compliance—specifically, the flatness deviation between both side rails must not exceed 2mm.

③ During inspection, verify whether material accumulation, unilateral feeding, or uneven material distribution occurs internally. When material buildup is detected, countermeasures include installing additional chain tensioners and increasing the density of chain cleaning wear pad. For feeding irregularities such as uneven distribution, corrective actions involve adjusting the feed direction or implementing side-feeding configurations.

④ After all the above checks are completed, judge according to whether the equipment is new or old.

For new equipment, the runout may be caused by cumulative chain tolerance errors on one side as mentioned earlier. In this case, although runout occurs, there is no wear on the wear pads or side plates, so no action is required and it will self-correct after some operation time. If wear has already occurred on the wear pads and side plates, a section of the chain can be removed and reinstalled after 180-degree rotation (rotating along the chain’s running direction as the axis). However, please note that this method is only applicable when the chain operation is not affected after the chain is reversed, and the vast majority of curved-section en-masse conveyors cannot use this method. If the above methods still cannot solve the chain runout and wear problem of new equipment, it is recommended to contact the equipment provider for chain replacement or other treatment methods.

For used equipment, severe sprocket/chain wear or rail deterioration typically causes runout – replace all worn components to rectify.

Thirdly, if the new and old chains are mixed, and the runout occurs after replacing the chain, if the runout does not cause wear with the side plate, no treatment is needed, and it will recover after a period of use. If wear occurs with the side plate, you can choose to flip the installation or replace the adjacent chain.

⑤ Certainly, regular inspection, maintenance and proper operating protocols are important guarantees to prolong the life of the equipment and ensure its normal operation in the specified manner. According to the “Engineering Application Manual of Conveyor and Special Chains” and the second edition of “Standard Chain Manual: Power Transmission Chains and Conveyor Chains”, the specified limit for chain pitch elongation generally ranges between 3% to 6% of the theoretical chain pitch, and chains exceeding this tolerance range require replacement.

Conclusion

Engineering chain runout of en-masse conveyors is an important factor affecting equipment operation and requires widespread attention. Systematic maintenance of chain tension, sprocket alignment, rail condition and intermediate section leveling significantly reduces runout occurrences. In addition, the perfect maintenance plan and real-time inspection system also lay the foundation for stable equipment operation. Through continuous running-in optimization, the efficient and safe operation of the en-masse conveyor is ensured, thereby improving production efficiency and safety.

Post Time: 2025-12-04