News & Events

-

GSS News | GSS Chengdu Technology Exchange Meeting Concludes Successfully

Recently, GSS Systems has visited to Chengdu, a key central city in western China, to engage in high-level exchanges with leading industry partners. During the meeting, all participating companies shared insights on the latest technology trends and discussed ways to enhance equipment performance...View More -

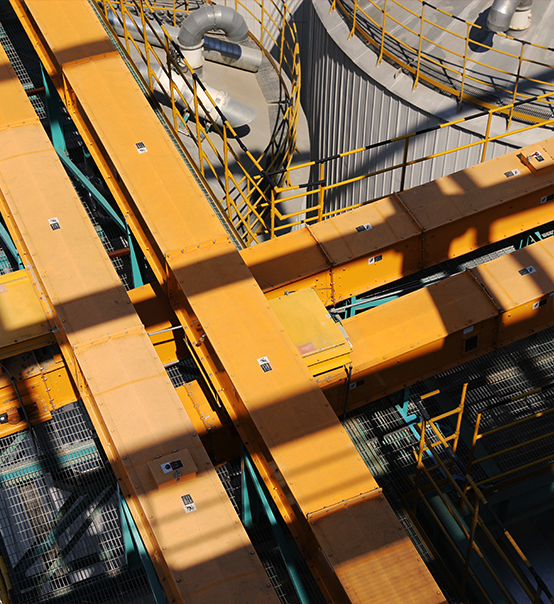

GSS Share | Introduction of En-masse Conveyors — Welded Curved Plate Chains

The welded curved plate chain is commonly and widely used in the grain and oil industry due to its simple structure and good overall performance. It consists of chain links, pin shafts, pins, and chain accessories. The chain links are formed by welding chain plates and bushes (see Figure). The ma...View More -

GSS Share | Introduction of En-masse Conveyors — Bush Roller Chains

The bush roller chain consists of inner chain plates, outer chain plates, bushes, pin shafts, rollers, and chain accessories (as shown in Figure). The chain plate is formed by the cutting process, and after precise machining, the roller is placed on the bush, which is then formed by interference ...View More -

Happy Chinese New Year!

Happy Chinese New Year! GSS Systems wishes you a happy new year filled with health, happiness and good fortune!View More -

GSS News | GPT and GSS Forge Strategic Partnership to Embark on a New Chapter!

On January 14, 2025, the industry-leading company Grain & Protein Technologies (GPT) and GSS Systems successfully established a strategic partnership. Mr. Goh Bak Yan, the president of GPT Asia Pacific, and Mr. Liu Feng, the president of GSS Systems, attended the ceremony along with their tea...View More -

GSS Share | Introduction of En-masse Conveyors — Die forged chains

The die-forged chain, also known as the detachable chain, features a compact structure, lightweight design, and less material. It consists of chain links, pin shafts, retaining rings, and chain accessories (as shown in Figure). The chain links are made of alloy steel by die forging or roll forgin...View More -

GSS Honors | GSS Systems Awarded “Outstanding Supplier of 2024″ by Wilmar!

As 2024 comes to an end, GSS was invited to attend the Wilmar 2024 Annual Supplier Conference, where we were honored with the "Outstanding Supplier" award. This recognition is a testament to GSS's long-standing excellence and contributions to the industry, as well as our...View More -

GSS News | Another successful collaboration with Wilmar!

In recent port renovation project, GSS supplied wide range of high-capacity conveying equipment, including Bucket elevators, En-masse chain conveyors, Air-supported belt conveyors and Continuous intake belt conveyors. GSS patented Continuous intake belt conveyor is known for its safety, sustaina...View More -

GSS News | GSS Supports Yihai Kerry to Build the Largest Grain and Oil Industry Base in Huanghuai Plain

GSS supports Yihai Kerry Modern Food Industrial Park to put into operation the project of processing 4,000 tonnes of soybeans and 400 tonnes of corn per day. The project can process 1.4 million tonnes of soybeans, 520,000 tonnes of refined fats and oils, 300,000 tonnes ...View More